Nanolutions

All Nanolution machines have been designed with patented wet particle size reduction Nano technology to process all forms of suspension and solution formulations, for example inks, paints & coatings, pharmaceuticals, food & beverage, cosmetics and chemicals.

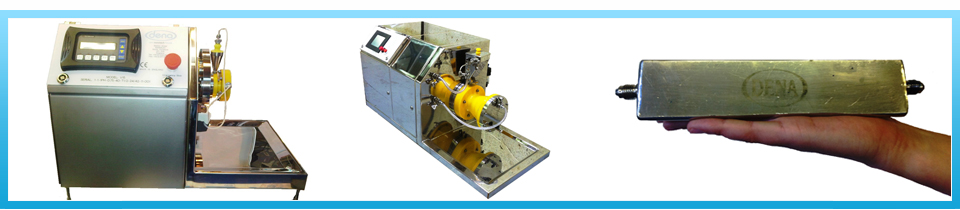

We design and manufacture each production machine to suite our clients’ requirements, supplying a wide range of Nano machinery, from batch sampling 15ml and above for R&D work on pharmaceuticals, chemicals, coatings, etc., up to full scale production systems of up to 30,000 litres volume for inks, paints, cosmetics, etc .

Processing to Nanometric scales – The key benefits:

- Reduce to Nanometric sizes for quick chemistry, homogeneity, blending and mixing to give high quality

- Cost effective

- Production of unique compounds

- Greater uniformity

- High and consistent quality

- Contamination free

- Tighter particle size reduction

- Reduced production time

The Dena reactors are designed to give the precise action required to mix and homogenise a specific material. Dena customers typically use this technology strategically to refine the quality and efficiency of their existing products. For example the pharmaceutical industry can use this technology with the objective of extending their existing patent’s life.

Pharmaceuticals

Dena’s technology is able to produce finer particles with much greater uniformity than other conventional types of system. The capability allows pharmaceutical companies to develop and produce drugs with a higher precision in terms of particle size to help new drugs to disperse quicker and more efficiently with increased bioavailability.

The work to develop such products as well as commissioning the necessary equipment normally requires tight collaboration with our customers.

Inks, Paints & Coatings

Dispersing pigments is essential to achieve a uniform and effective paint, ink, coating, dye, emulsion, ceramic / colour or pigment; our advanced process can be used to achieve this.

Where a conventional mixing device is used the Dena system will typically reduce processing time. The precise application of energy results in better homogeneity as the mixture cannot leave the system until it has been fully processed. Energy applied to the system is used more efficiently, cleaning is simple and a shorter cycle increases production. This is a closed system which means protection from hazardous materials and no contamination so clean room conditions are not required and as there are no spaces within the system wastage is virtually eliminated.

Cosmetics

All products, including lipstick, gels, lotions and creams can be processed with a single pass and recycling of waste materials is not necessary in most cases.

Food & Beverage

The Dena technology for process intensification can be use in a wide range of areas within the food & drinks industries such as: Sauces, Baby Food, Ice Cream, Food Colouring / Flavouring, Soft Drinks, Beer/Alcohol Yeast, etc.

The production of finer particles with much greater uniformity allows superior preparation of ingredients which will be reflected in an enhanced final product. The greater surface reaction area due to the finer particles allows for better emulsification greatly decreasing the ability of the final product to separate out.

Chemicals

With the Dena system reducing the particle size, uniformity allows chemical companies to develop liquid / solids / gas / oil combinations, emulsions, suspensions and produce even higher quality products.

The Technology

Nanometric Sampling System is designed to utilise three different functions in one piece of equipment; de-agglomeration, particle size reduction and homogenise to process various suspended materials down to Nanometric scale, see examples below: –

- Coatings

- Nanometric inks

- Industrial & Nanometric paints

- Dyes

- Pigments

- Chemical suspensions

- Creation of Nanometric particles

- Chemical applications

- Pharmaceutical applications